Primer powder coat. For a smooth and strong adhesion between substrate and finishing layer.

In particular, porous metals such as aluminum, copper, zinc, lead, a primer is the best treatment for improved adhesion and flow properties of all powders.

This primer can be used as a substrate on rims for a better result under chrome.

Product; Powder coat powder

Structure; smooth

Brand; STpowders

Color name; jet black

RAL Nr; 9005

Gloss level: gloss

Application; Primer under chrome

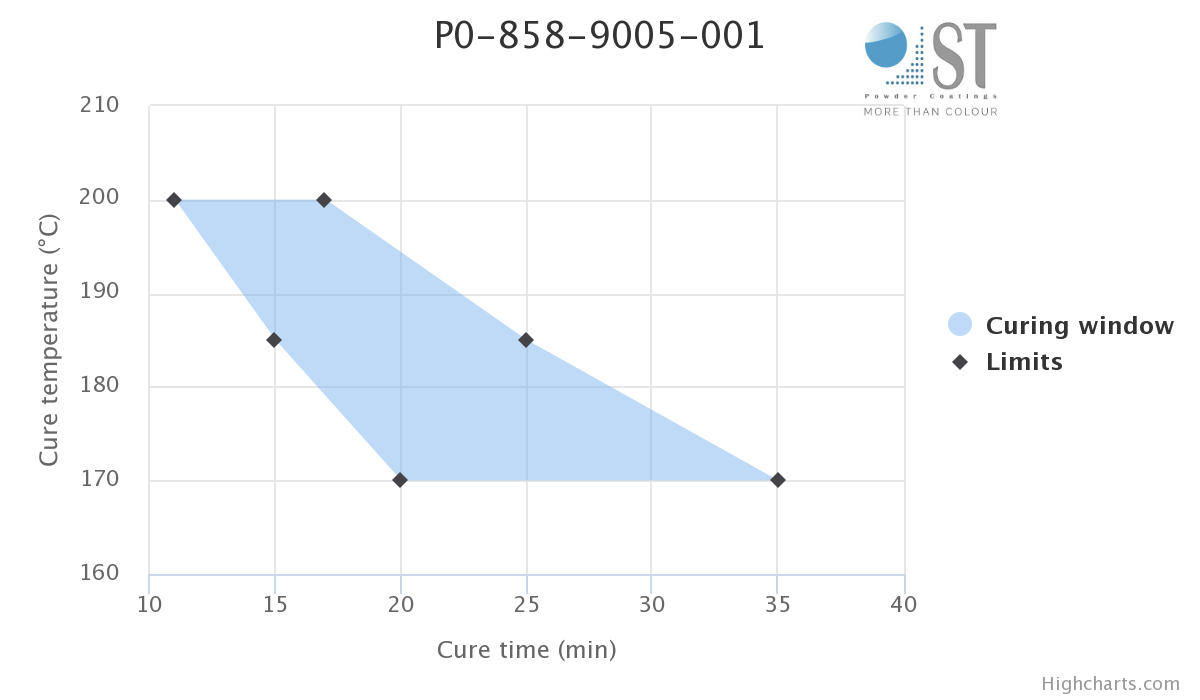

Muffle temperature ° C; 180

Muffle expensive; 20 min

Content: Only in 250 gram

Coverage: 1.5 m²

Processing:

Primer is processed in the same way as a finishing coat

1) degreasing parts - blasting / sanding - dusting / removal

(Porous metals such as aluminum, bronze, zinc, copper, alloys must first be degassed. 30 min> 200 ° C) and cool.

2) primer spraying.

3) Baking (time starts when the parts have reached the baking temperature.)

4) Switch the oven off and let it cool down in the oven to room temperature

5) Powder coating finishes.